Secret Benefits of Using a Membrane Switch in Industrial Applications

Secret Benefits of Using a Membrane Switch in Industrial Applications

Blog Article

Checking Out the Advantages of Membrane Layer Changes in Modern Electronic Equipment

The integration of membrane changes right into modern-day digital equipment presents several compelling benefits that warrant factor to consider. The cost-effectiveness of membrane layer switches positions them as a practical choice for makers looking for to enhance their item offerings.

Layout Adaptability

Layout flexibility is a pivotal advantage of membrane switches, enabling manufacturers to create customized interfaces that meet particular operational requirements. This adaptability is vital in an age where individual experience and performance are vital. Membrane switches can be designed in various shapes, sizes, and shades, allowing for visual assimilation right into varied digital gadgets.

The published graphics can be tailored to match branding, while the tactile feedback can be readjusted to boost individual communication. Furthermore, membrane switches can integrate multiple layers, enabling features such as backlighting and protective overlays, which add to both aesthetic charm and functionality.

Manufacturers can also make use of numerous products, such as polyester or polycarbonate, to align with particular application needs. This flexibility encompasses the configuration of the button layout, allowing the assimilation of several functions within a single user interface.

The ability to personalize not only boosts the functionality of electronic devices yet likewise allows for the consolidation of sophisticated technologies, such as capacitive touch. As an outcome, membrane buttons are an optimum option for a wide selection of applications, varying from medical equipment to consumer electronics, making certain that user needs are constantly satisfied.

Resilience and Long Life

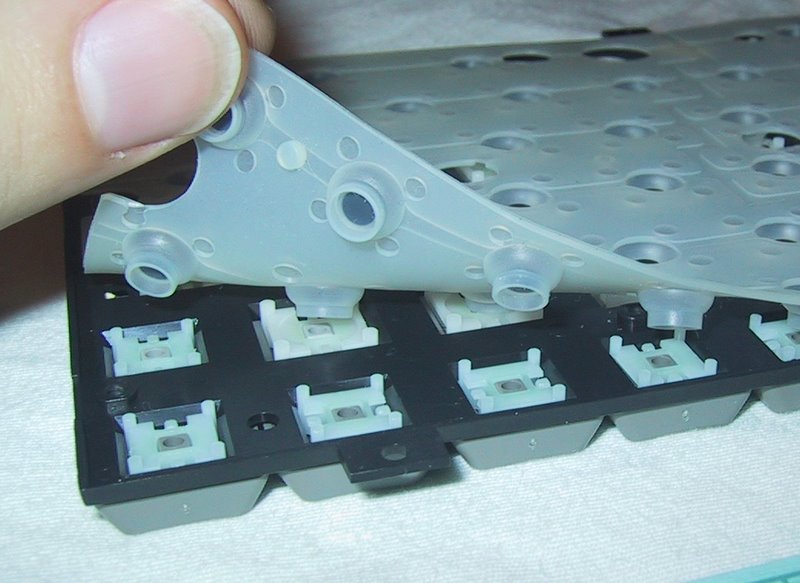

Sturdiness and longevity are essential elements that boost the charm of membrane layer switches in contemporary electronic devices. These buttons are created to withstand difficult settings, including exposure to dampness, dust, and different chemicals. The robust materials utilized in their building and construction, such as polyester and polycarbonate, contribute dramatically to their resistance against abrasion and effect, making certain that they maintain performance also under exhausting problems.

In addition, membrane layer switches are inherently sealed, protecting against contaminants from infiltrating the interior elements. This covered construction not only extends the life-span of the buttons however additionally decreases the regularity of upkeep and replacements, which is a crucial element for suppliers and end-users alike.

One more advantage is their ability to sustain extensive cycles of operation without degradation in efficiency (Membrane Switch). This particular makes them specifically ideal for applications calling for constant usage, such as clinical tools, industrial machinery, and consumer electronics

Cost-Effectiveness

Additionally, membrane layer switches are pop over to this web-site typically generated utilizing cost-efficient products and processes. Their light-weight style not just lessens shipping expenditures however additionally enables easier assimilation into digital devices. This can bring about further financial savings in producing prices, as streamlined setting up processes minimize labor and time requirements.

Additionally, the inherent simpleness of membrane switch layouts typically suggests fewer parts are needed compared to typical mechanical switches. This decrease in components not only decreases manufacturing expenses yet also lessens factors of failure, improving integrity and performance.

In fields where budget restrictions are essential, such as consumer electronic devices and commercial applications, the cost-effectiveness of membrane switches comes to be particularly helpful. Their ability to deliver regular performance at a lower lifecycle expense placements them as a prudent option for modern-day digital equipment. In general, buying membrane layer buttons can bring about significant long-term savings for services and customers.

Modification Options

Customization options for membrane switches are substantial, allowing makers to customize these parts to fulfill specific application requirements. One of the primary advantages of membrane switches is their flexibility in style. Producers can select from a variety of materials, including polyester, polycarbonate, and acrylic, each offering distinct benefits in terms of resilience and aesthetics.

Additionally, membrane switches can be customized in various forms and dimensions to fit special gadget setups. This versatility extends to the incorporation of various shades, graphics, and structures, allowing brands to maintain their aesthetic identification while improving individual experience (Membrane Switch). Additionally, manufacturers can incorporate responsive comments features, such as printed secrets or varying actuation pressures, to enhance usability

The printing technology used for graphics and tales can my response also be customized, making certain high-resolution pictures and long-lasting prints immune to use and tear. Backlighting options, such as LEDs, can be included to improve presence in low-light atmospheres. Custom circuit layouts allow for specific functionalities, making it possible for manufacturers to produce buttons that cater specifically to their product's requirements. Overall, these substantial modification options make membrane layer switches over a compelling option for modern-day electronic devices.

Applications in Different Industries

Membrane layer buttons locate considerable applications across a variety of industries, demonstrating their versatility and performance in many setups (Membrane Switch). In the medical care field, they are generally made use of in clinical tools, such as patient monitors and diagnostic tools, where integrity and convenience of cleansing are extremely important. Their secured layout aids protect against contamination, making them ideal for environments that call for stringent hygiene requirements

In the automobile industry, membrane buttons play an important function in control panels and dashboards, providing an intuitive user interface for motorists. The responsive comments and customizable features boost customer experience while making certain longevity versus vibrations and environmental variables.

Furthermore, in commercial applications, membrane layer switches are used in machinery control systems, permitting straight and effective customer interaction. With their flexibility, membrane layer switches offer a durable service that meets the diverse demands these days's technology-driven industries, proving crucial for both capability and aesthetic allure.

Verdict

In verdict, membrane layer switches over deal substantial benefits in modern-day digital tools due to their layout adaptability, longevity, and cost-effectiveness. The Clicking Here light-weight nature of membrane layer switches over more adds to minimized delivery expenses and simplicity of combination.

Report this page